Recycling magnets from the factory floor

A new recycling method developed by scientists at the Critical Materials Institute, a U.S. Department of Energy Innovation Hub led by Ames Laboratory, recovers valuable rare-earth magnetic material from manufacturing waste and creates useful magnets out of it. Efficient waste-recovery methods for rare-earth metals are one way to reduce demand for these limited mined resources.

“We wanted to see if we could save that extra step of metals separation, because it’s not just an extra step, it’s an expensive and time consuming one.”

The process, which inexpensively processes and directly reuses samarium-cobalt waste powders as raw material, can be used to create polymer-bonded magnets that are comparable in performance to commercial bonded magnets made from new materials. It can also be used to make sintered magnets (formed by pressure compaction and heat).

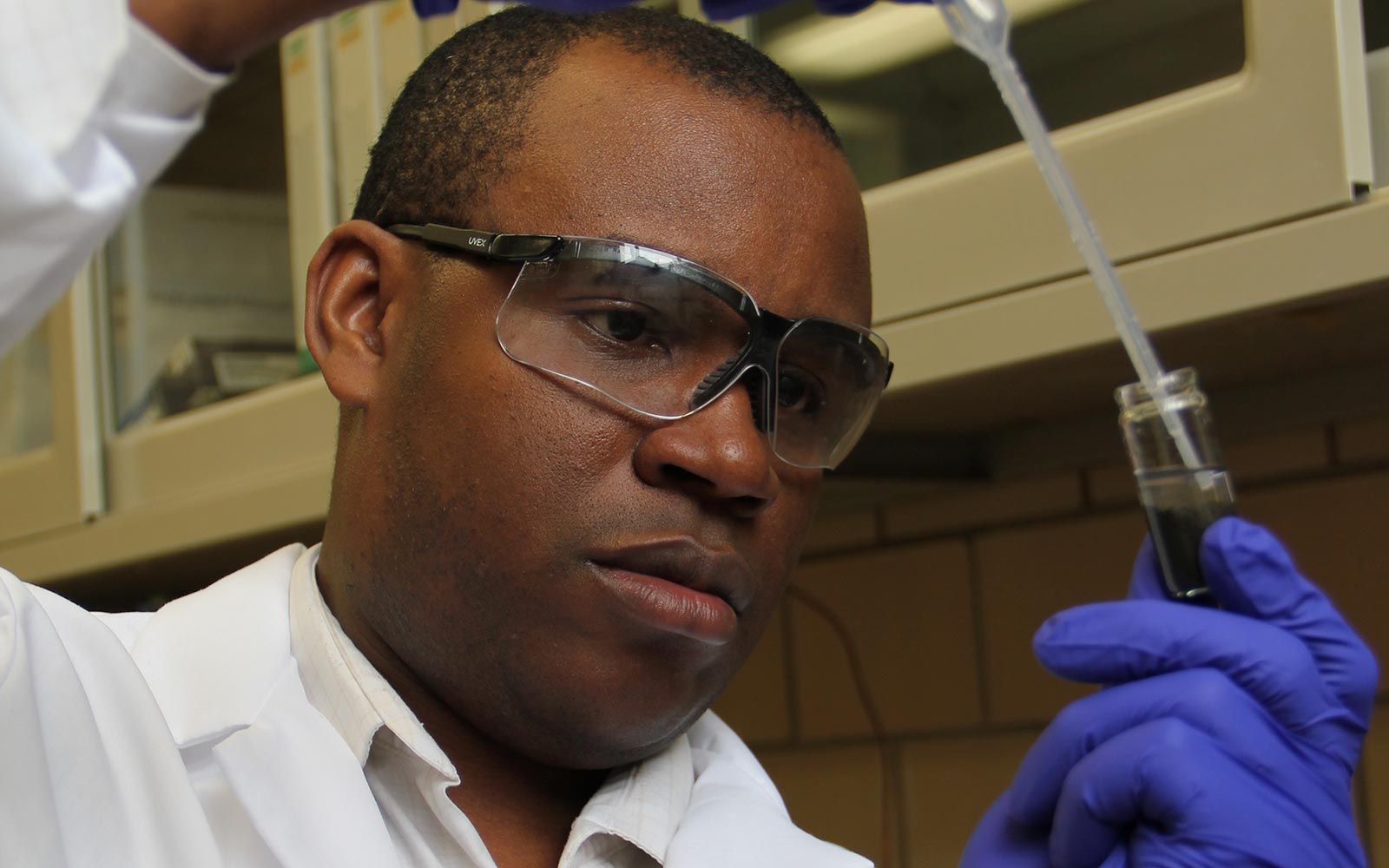

Ames Laboratory scientist Ikenna Nlebedim is leading the effort to optimize the recovery process.

Click here to read the full story.